Authors:

Xiaofeng Wu

Ningbo China Institute for Supply Chain Innovation (NISCI)

75

Summary:

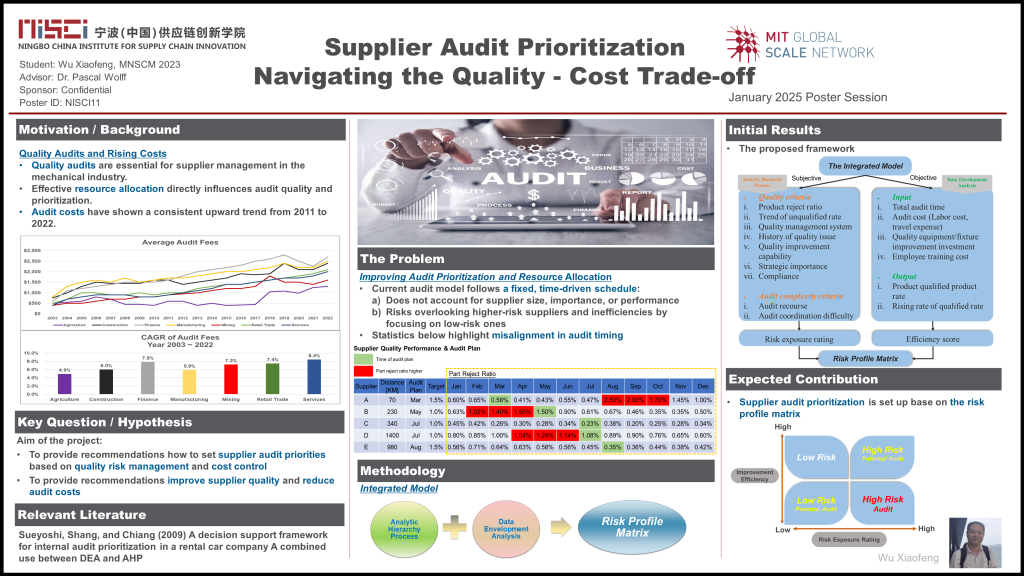

Supplier quality audits play a crucial role in the mechanical industry. Appropriate distribution of audit resources direct impact on the audit work and prioritization. The time-driven supplier quality audit model is implemented. To provide recommendations how to set supplier audit priorities based on quality risk management and cost control.

Leave a Reply